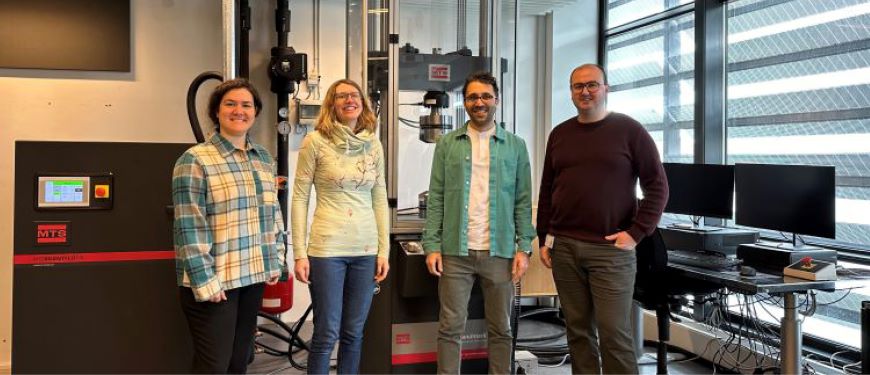

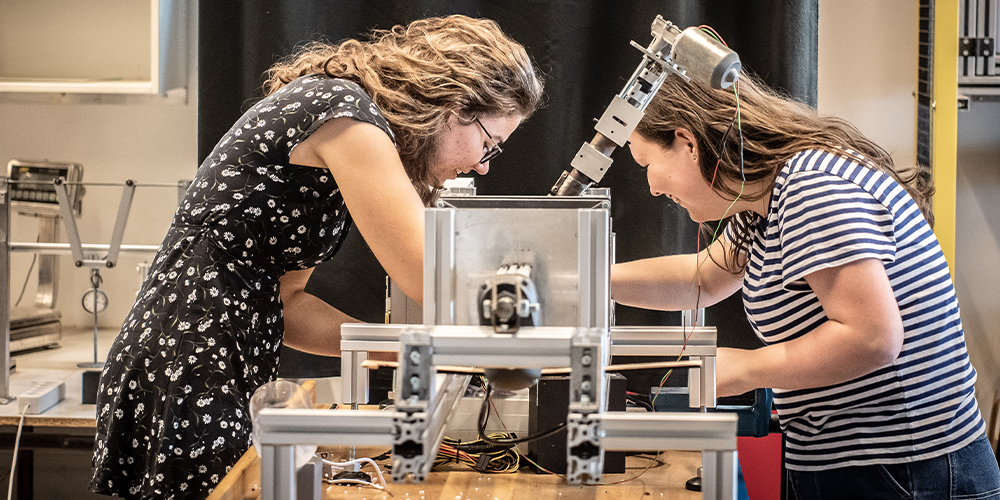

Group Core Focus

The Smart Structures and Manufacturing (SSM) Group at SDU advances the design, modelling, and experimental characterization of next-generation structural and multifunctional materials. Our research spans fatigue and fracture mechanics, additive and surface engineering, multiscale material modelling, and computational design of advanced metamaterials. By combining state-of-the-art testing facilities with high-fidelity FEM/XFEM simulations, multiscale homogenization, and digital image correlation, the group develops robust methodologies for understanding and optimizing the behavior of anisotropic, cellular, and additively manufactured materials. We integrate modeling and experiments across scales—from microstructural evolution in AM processes to structural performance at the macroscale—to enable stronger, lighter, and more intelligent materials and components for demanding industrial applications.

Key Competencies and Expertise

- FEM and XFEM modeling of fatigue, fracture, and complex material behaviour

- Experimental fatigue, tensile, tribology, and impact testing of advanced materials

- Additive manufacturing process analysis and surface integrity evaluation

- Multiscale FEM modeling and homogenization of anisotropic and cellular materials

- Digital Image Correlation (DIC) for full-field strain and deformation measurement

- Computational design and optimization of multifunctional metamaterials

- Simulation-driven design of piezoelectric, mechanical, and architected materials

- Multiscale modeling and optimization of LPBF and other AM processes

- Structural simulation and performance prediction under complex loading

List of Lab Equipment

- MTS Landmark fatigue testing machine (up to 100 kN)

- ZwickRoell tensile testing machine (up to 10 kN with 500 N and 10 kN load cells)

- Rtec Instruments Tribometer for friction and scratch testing

- Ametek LLOYD tensile testing machine (up to 30 kN with multiple load cells)

- Climate chamber for controlled temperature testing (−129 °C to 330 °C)

- Dynamic Mechanical Analysis (DMA Q800) with force range 0.0001–18 N

- Universal hardness testing equipment

- Charpy impact testing machine

- Digital Image Correlation (DIC) system for full-field strain measurement

Contact:

Head of the Group: Mohammad Malekan

Email: malekan@sdu.dk/ Phone: +4565508607