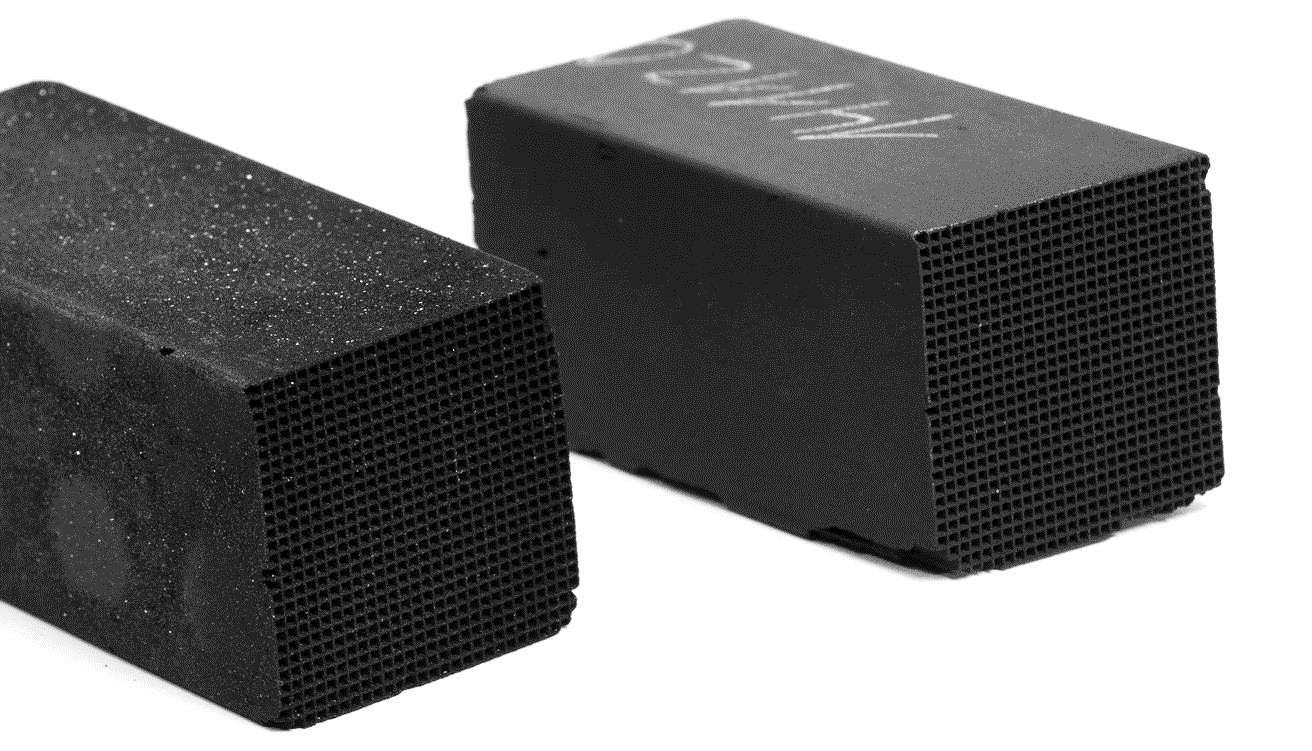

Left: 4H-SiC monolith without copper as co-additive

Right: 4H-SiC monolith with copper as co-additive

Alloying metals together with a view to modifying their properties originates with the Bronze Age. Recently, we discovered that an alloy of aluminium and copper has advantageous effects compared with aluminium alone as a reaction sintering aid, when creating macroporous silicon carbide monoliths for use as a combined diesel particle filter and catalyst support system. Our invention minimises the formation of undesirable ternary carbide crystals (the glistening crystals in the top left image) and results in a superior product with a macroporous microstructure of highly interconnected anhedral crystals of 4H-SiC. Furthermore, the copper plays a crucial role during a subsequent oxidation process in creating a coherent layer of SiO2 that covers the entire microstructure and enhances the mechanical stability of the monolith.

● This technology is currently licensed by SDU to Dinex A/S

Recent publications

“The role of aluminium as an additive element in the synthesis of porous 4H-silicon carbide”

Jeanette Hvam, Per Morgen, Eivind M. Skou, Ulla Gro Nielsen, Thomas Wolff, Terence E. Warner, Journal of the European Ceramic Society 36, Pages 3267–3278 (2016).

“The effect of trace amounts of copper on the microstructure, stability and oxidation of macroporous silicon carbide” Jeanette Hvam, Per Morgen, Eivind M. Skou, Thomas Wolff, Terence E. Warner, Journal of the European Ceramic Society, 36, Pages 3279–3284 (2016)

Contact details: