Anders Struve

Master Thesis - Environmental Engineering - 2020

The increasing temperature and the prolonged drought periods are stressing the different forest ecosystems and are affecting some more vulnerable species to their extinction affected by tree diseases and pathogens. A clear example is the bark beetle that affects different types of softwood, Fir (Abies alba) and Spruce (Picea abies) or the fungus Hymenoscyphus fraxineus from Asia affecting a big part of the European ash trees. The Climax forest ecosystems known as the most stable and perdurable in time are being pushed out of their comfortable dominant position leaving the door open to other colonizable species that has better climate adaptability but a lower wood quality.

Quality wood can be described in different ways, depending on the use and the person involved in the process. A forest engineer would describe quality to wood density and fiber length, and the sawmill will describe the log quality as the straightness and the minimum number of knots together with diameter to minimize the losses up to a specific diameter.

Following the description from Food and Agricultural Organization defines quality as all the characteristics that affect the value recovery chain and serviceability of end products.

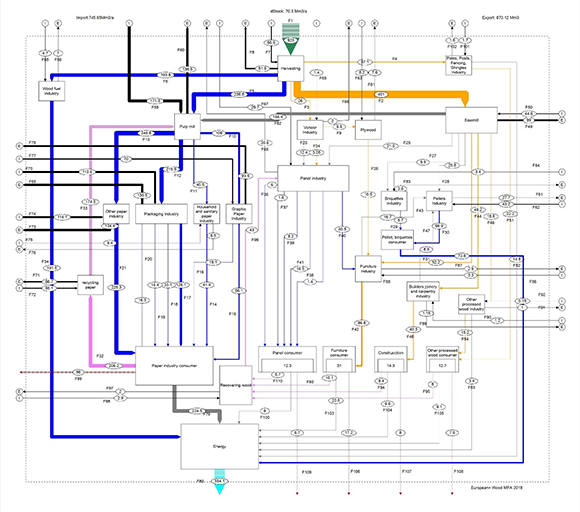

A material flow analysis was used to quantify the European and Russian region wood consumption, finding 110 flows and 27 processes that transforms the roundwood harvested to the final products. Top-down approach was used to develop the first part of the system quantifying the first transformation for the sawnwood industry and second transformation for the paper and fuel industry and the bottom-up approach for the second transformation of sawnwood industry.

Click on the Flow Diagram to see a larger version

Wood Industry has three main industries, paper, fuel for the non-quality wood consuming 50 percent of harvested logs and the other half is quality wood consumed by sawmills and veneer industry. From this quality wood, only 48% will end as final product and the residues from the industries will be used in board industry, pellet and briquettes, and pulp industry. The furniture, carpentry and other processed industries reducing even more the efficiency of the final quality wood products with 10 % losses.

The bottleneck of all the system is the wood used in sawmills and veneer industry needing specific roundwood quality characteristics. Climate change can affect the growth of the trees and the existence of some species affecting the availability of this type of wood not just the furniture and carpentry industry but other industries like panel that are linked to sawnwood residues.