Vibration Demo Room

Our Vibration Demo Room is equipped for experimental and operational vibration testing, supporting research in structural dynamics and monitoring.

The Vibration Demo Room includes the following equipment and facilities:

- Sensors: Accelerometers, strain gauges, load cells, and geophones for precise measurements

- Excitation Devices: Electromagnetic shakers and impact hammers for controlled dynamic loading

- Data Acquisition: Portable and high-performance systems for real-time signal capture and analysis

- Teaching space: Including whiteboard and audiovisual equipment.

Our facilities enable hands-on demonstrations, algorithm validation, and advanced testing under controlled laboratory settings or under real-life operational conditions.

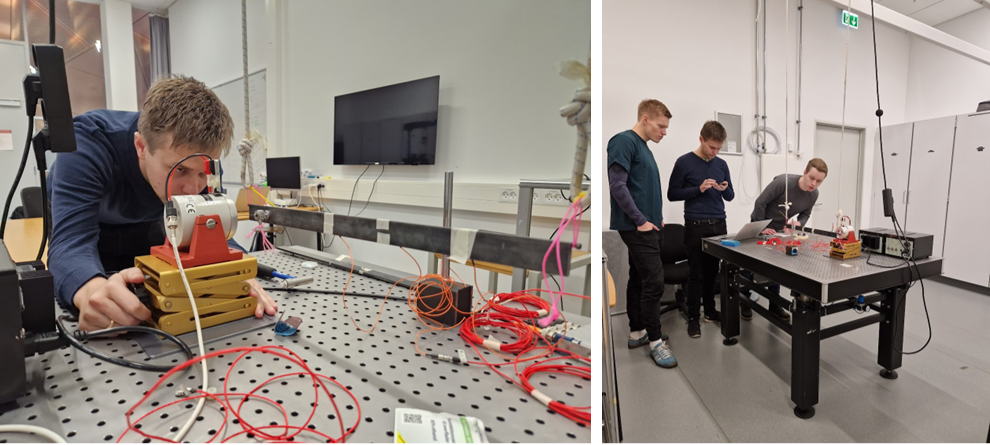

Figure 1: The Vibration Demo Room features state-of-the-art sensors and data acquisition systems for experimental and operational vibration testing

Figure 2: In the Vibration Demo Room we teach our master students how to perform experimental and operational vibration testing using state-of-the-art equipment andadvanced data analysis methods.

Machine Dynamics Laboratory

This laboratory focuses on rotating machinery diagnostics. It features a SpectraQuest Wind Turbine Drivatrain Diagnostics Simulator (DDS) platform, designed for development and validation of vibration-based condition monitoring algorithms for bearings and gears.

Our DDS platform features:

- Controllable Speed and Load: Allowing replication of realistic operational scenarios.

- Two-Stage Speed Reduction: Incorporating a parallel-axis and a planetary gearbox, emulating the configuration of conventional wind turbine drivetrains.

- Exchangeable gears and bearings: Facilitating the introduction of typical damages in bearings (inner race, outer race, ball, combined) and gears (missing or chipped tooth, root crack gear, surface wear).

- High-frequency acceleration measurements and tachometer signals distributed on multiple critical locations.

The facility supports research on condition monitoring, fault detection, and predictive maintenance for wind energy systems and other rotating machinery.

Spectra-Quest Wind Turbine Drivetrain Diagnostics Simulator platform with additional instrumentation for vibration-based CM