Millions ensure LSP at Lindø: Partners start large-scale production

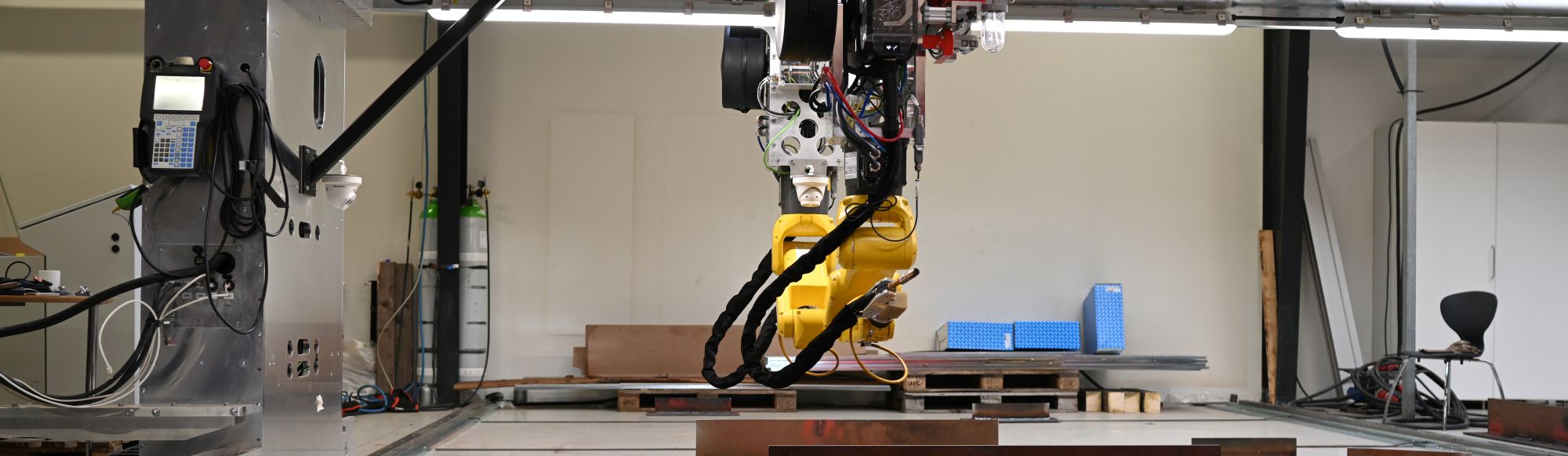

SDU and several partners are now initiating the establishment of the world's first centre for the development of automation and robots for building large structures such as wind turbines, ships, and buildings. The Large Structure Production Centre will receive DKK 88 million to build a unique laboratory on a large scale - and the companies cannot wait to get started.

With a supporting grant of DKK 88 million, SDU and several partners can now realise plans for the world's first centre for the development of robot and automation solutions to produce everything from wind turbines to buildings and ships.

It is an enthusiastic leader of the upcoming Large Structure Production Center (LSP), Professor Christian Schlette from SDU Robotics, who has received the news that he can start the work.

- It is fantastic. Now we can, together with our partners, write the next chapter in the Danish robot adventure. One of the first things we must do is hire people and buy equipment so that we begin setting up at the Port of Odense on Lindø. We will also start three demonstration projects immediately, together with the business partners, and over time we will build an actual production and development hall, says the professor.

Professor Christian Schlette

Professor Christian Schlette

- The centre on Lindø may be essential in ensuring sustainable and digital development and research in several areas that form the foundation of our society. It is about the energy sector, the maritime sector and not least the construction industry, says Christian Schlette.

When SDU and Schlette move into Lindø, it will be, among other things, to work on three projects – use-cases - together with more than 15 companies that contribute to LSP with man-hours and resources. Overall, LSP is expected to reach a budget of DKK 200 million over the next five years.

- For a company our size, LSP represents an opportunity to develop technology and solutions on a scale that we otherwise would never come close to because it is so large. There is a huge potential in automation in the work with large structures because it is not being used. It's just easier to buy a small robot and put it into its factory, than to think of robots in a large production of, for example, a bridge or a shipping sector. We are very excited that there will be the opportunity to do so on Lindø now, says Gert Jørgensen, who founded Inrotech with his brother, who is himself a former welder at Lindø shipyard.

In just a few years, Copenhagen's Cobod has established an international growth company, which today numbers 80 employees. The company is behind large-scale 3D printers for construction with equipment that enables customers to print three-storey houses or wind turbine towers directly on the construction site. Cobod is also a partner at LSP and looks forward to developing new technology on Lindø.

- The centre is a huge step forward and will be able to deliver development for the 10 years that lie ahead and more. Today, the construction industry is characterised by virtually no automation because the structures we are talking about are so large. But with LSP, we will get facilities so that we can develop the necessary new tools, says CEO of Cobod, Henrik Lund-Nielsen, who only exports his 3D printers.

- Cobod will have access to a 600 square meter test environment where we can develop our technologies so that we not only print the building but also enable robots to plaster and sand the walls and perhaps paint the house and put windows in. It is a development that we do not have the opportunity to execute, as it would require too many resources, says CEO Henrik Lund-Nielsen, Cobod.

- We have already come a long way with digitisation and automation in Denmark. But if we are to maintain our competitiveness and maintain the industry on Funen, then our companies will have to be two steps ahead of development - and the competitors. This was what enabled us to continue building ships at the Lindø shipyard for many years after the rest of the shipyards in the country were closed. I am therefore very much looking forward to the new centre bridging new knowledge on robot technology and industry. It is a very ambitious project that we have created, and I know that many have turned their eyes to Lindø to see what we can do on Funen, says Claus Jensen.

Even though there is not yet a hall with LSP on the door, the director of the Port of Odense, Carsten Aa, is convinced that the centre can help open the door to a new robot adventure. At the same time, it will create a necessary boost in several other industries.

- With SDU and the LSP centre, companies at the port will have a new neighbour that will be able to push today's production methods into a new era. Robots will play a crucial role for manufacturing companies in global competition. The companies at the Port of Odense must simply be able to produce smarter, faster and deliver better quality than the competitors. If Denmark is to continue to be the factory for the green transition, with leading companies such as Vestas and Bladt Industries here at the Port of Odense, the introduction of robot technology in heavy production is crucial, he says.

The Funen business hub received a total of DKK 108 million, which will be distributed as follows. LSP will receive DKK 87.6 million, the drone test centre at HCA Airport will receive DKK 8.6 million. DKK, development of automated ferries on South Funen receives DKK 7.9 million, while there is DKK 1.6 million for the establishment of the so-called Robotternes Hus/House of Robotics. The remaining funds will go to the management and administration of the projects.

Press contact: The Faculty of Engineering - Jakob Haugaard, journalist - 40315261

It is an enthusiastic leader of the upcoming Large Structure Production Center (LSP), Professor Christian Schlette from SDU Robotics, who has received the news that he can start the work.

- It is fantastic. Now we can, together with our partners, write the next chapter in the Danish robot adventure. One of the first things we must do is hire people and buy equipment so that we begin setting up at the Port of Odense on Lindø. We will also start three demonstration projects immediately, together with the business partners, and over time we will build an actual production and development hall, says the professor.

Professor Christian Schlette

Professor Christian Schlette Largest Component

LSP is the largest component in the Funen business hub, which has 65 partners in the consortium, Nextgen Robotics. The Danish Board of Business Development has distributed a total of DKK 595 million between eight Danish business hubs. Funen has received 108 million kroner, where almost 88 million goes to LSP.- The centre on Lindø may be essential in ensuring sustainable and digital development and research in several areas that form the foundation of our society. It is about the energy sector, the maritime sector and not least the construction industry, says Christian Schlette.

When SDU and Schlette move into Lindø, it will be, among other things, to work on three projects – use-cases - together with more than 15 companies that contribute to LSP with man-hours and resources. Overall, LSP is expected to reach a budget of DKK 200 million over the next five years.

Excited partner

One of the partners is the Funen company Inrotech, which develops and produces mobile welding robots for, for example, offshore, bridges and shipyards. They will collaborate with SDU researchers and Bladt Industries, which produce wind turbine foundations in the port areas.- For a company our size, LSP represents an opportunity to develop technology and solutions on a scale that we otherwise would never come close to because it is so large. There is a huge potential in automation in the work with large structures because it is not being used. It's just easier to buy a small robot and put it into its factory, than to think of robots in a large production of, for example, a bridge or a shipping sector. We are very excited that there will be the opportunity to do so on Lindø now, says Gert Jørgensen, who founded Inrotech with his brother, who is himself a former welder at Lindø shipyard.

In just a few years, Copenhagen's Cobod has established an international growth company, which today numbers 80 employees. The company is behind large-scale 3D printers for construction with equipment that enables customers to print three-storey houses or wind turbine towers directly on the construction site. Cobod is also a partner at LSP and looks forward to developing new technology on Lindø.

- The centre is a huge step forward and will be able to deliver development for the 10 years that lie ahead and more. Today, the construction industry is characterised by virtually no automation because the structures we are talking about are so large. But with LSP, we will get facilities so that we can develop the necessary new tools, says CEO of Cobod, Henrik Lund-Nielsen, who only exports his 3D printers.

- Cobod will have access to a 600 square meter test environment where we can develop our technologies so that we not only print the building but also enable robots to plaster and sand the walls and perhaps paint the house and put windows in. It is a development that we do not have the opportunity to execute, as it would require too many resources, says CEO Henrik Lund-Nielsen, Cobod.

Danish Metal: LSP builds a bridge

The idea of LPS received early support from Vækstteam Fyn, Chairman Claus Jensen, Dansk Metal’s Chairman, is pleased that the partners can now realise LSP, which was presented at a large conference in August at Lindø.- We have already come a long way with digitisation and automation in Denmark. But if we are to maintain our competitiveness and maintain the industry on Funen, then our companies will have to be two steps ahead of development - and the competitors. This was what enabled us to continue building ships at the Lindø shipyard for many years after the rest of the shipyards in the country were closed. I am therefore very much looking forward to the new centre bridging new knowledge on robot technology and industry. It is a very ambitious project that we have created, and I know that many have turned their eyes to Lindø to see what we can do on Funen, says Claus Jensen.

Even though there is not yet a hall with LSP on the door, the director of the Port of Odense, Carsten Aa, is convinced that the centre can help open the door to a new robot adventure. At the same time, it will create a necessary boost in several other industries.

- With SDU and the LSP centre, companies at the port will have a new neighbour that will be able to push today's production methods into a new era. Robots will play a crucial role for manufacturing companies in global competition. The companies at the Port of Odense must simply be able to produce smarter, faster and deliver better quality than the competitors. If Denmark is to continue to be the factory for the green transition, with leading companies such as Vestas and Bladt Industries here at the Port of Odense, the introduction of robot technology in heavy production is crucial, he says.

Facts

LSP is the largest component in the Funen business hub, which has 65 partners in the consortium, Nextgen Robotics. The Danish Board of Business Development has distributed a total of DKK 595 million between eight Danish business hubs. In addition to LSP, Nextgen Robotics consists of drone developments at HCA Airport and autonomous shipping on South Funen, where SDU is also involved, as well as the establishment of Robotternes Hus/House of Robotics.The Funen business hub received a total of DKK 108 million, which will be distributed as follows. LSP will receive DKK 87.6 million, the drone test centre at HCA Airport will receive DKK 8.6 million. DKK, development of automated ferries on South Funen receives DKK 7.9 million, while there is DKK 1.6 million for the establishment of the so-called Robotternes Hus/House of Robotics. The remaining funds will go to the management and administration of the projects.

Contact:

Christian Schlette, Professor, SDU Robotics - 93507377Press contact: The Faculty of Engineering - Jakob Haugaard, journalist - 40315261