Nimble-fingered robots win gold

Robot researchers from SDU have developed robots that are so dexterous that they can use screwdrivers to screw in small screws. The researchers behind the groundbreaking technology have won first prize at the world's most prestigious robot competition, World Robot Challenge.

With 211 industry robots for every 10,000 employees, Denmark is the sixth most automated country in the world. This is according to the latest report from the international robot federation, IFR.

At the same time, the consultancy firm McKinsey has revealed that automation could create around 25,000 new jobs by 2030. But companies need flexible robot solutions that can find small gadgets in boxes and put them together to create new products.

- Industry's big challenge is to get robots to master assembly processes. That requires fine motor skills and an overview. If you think about it, it's the sum total of many complicated processes. The robot has to pick out a small object from a box of many objects, then take it up and place it on another object, explains Professor Henrik Gordon Petersen from SDU Robotics.

Robots handle screws

Along with 13 other robot researchers from SDU, he has developed a new production cell with robots that, using the latest technology in computer vision, software and robot control, have become so nimble-fingered that they can handle screws, nuts and bolts, and screw things together to create new products.

The robot cell has won world recognition by winning the category Industry Robots at the world's biggest robot competition, World Robot Challenge in Japan.

- It's fair to say that we're the best in the world at solving industry's problems by automating complex tasks, such as assembling objects that are lying scattered in a box, says Henrik Gordon Petersen.

The world's leading technology

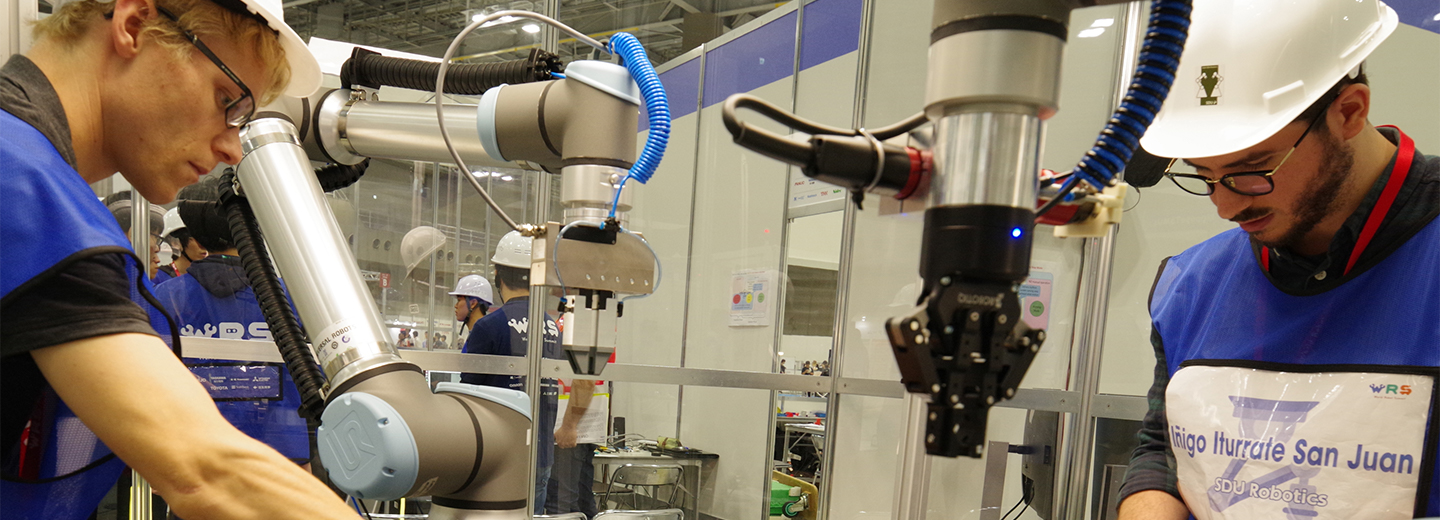

The production cell consists of a workbench at which two robot arms from Universal Robots work across from each other. The ceiling over the bench is covered with cameras, which are the robots' eyes. The robot arms are equipped with 3D-printed grippers that can pick up and handle very small objects made from both hard and soft materials.

- The unique thing about our cell is that it's so flexible. It's an open cell, which makes it easy to expand into a larger production installation. In addition to fully automated operation, the installation makes it possible for the robots to work closely with humans, explains robot researcher Christian Schlette from SDU Robotics, who was leader of the robot team in Japan.

According to the researchers, the production environments of the future will consist of robots, so-called cobots, that work side by side with humans. The two robots in the work cell have also mastered collaboration to a high level.

- At the competition in Japan, one of the robots held an item, such as a motor, while the other robot screwed it into the product that was being made. The robots can also figure out how to pass an item to the robot who has the necessary tool, explains Christian Schlette.

Mest avancerede Industri 4.0 Lab

The robot cell has now moved into SDU Industry 4.0 Lab. The University has invested over DKK 100 million in the laboratory and has ambitions of creating the Nordic region's most advanced I 4.0 Lab, where companies, researchers and students can together develop even more skilled robots, smarter production and innovative products.

When the laboratory is completed in 2019, it will contain 17 production cells supplemented by a wide range of other technology, such as mobile robots.

- The competition demonstrates that both nationally and internationally, we are at the cutting edge. The aim is to make sure our companies have the best options in a highly competitive market. The robot cell is an extremely good example of the potential for flexible production that an advanced production cell offers. So just think of the possibilities when we start putting them together and bringing in collaborative elements where people work closely with robots, says Head of Department Kasper Hallenborg from the Maersk Mc-Kinney Moller Institute, SDU.