Advanced simulation-based design optimisation methods, such as topology optimisation, are used to generate novel and high-performing heat sink geometries for electronics cooling applications.

Additive manufacturing is used to produce the complex geometries, which often cannot be manufactured in any other ways.

Due to the current high cost of metal AM, investment casting is being investigated as a low-cost alternative.

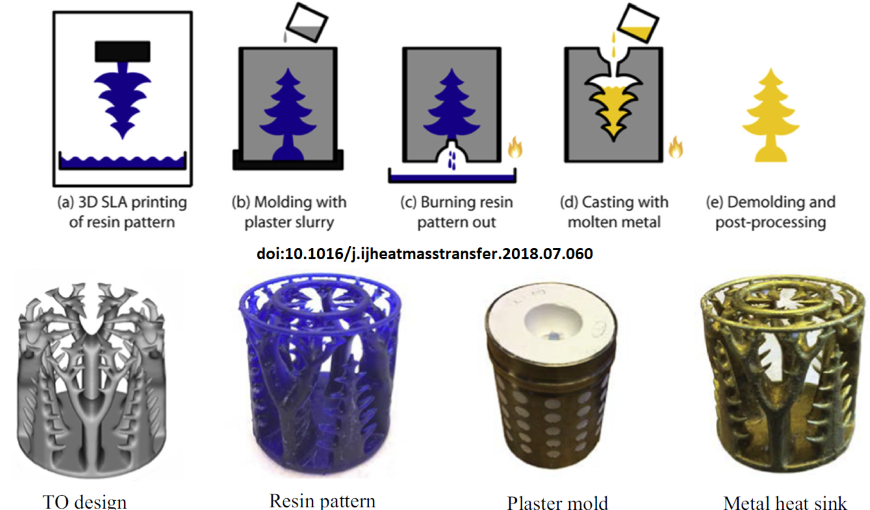

Investment casting is the process of making a mould around a plastic or wax copy of the specimen, burning it out and pouring melted metal into the cavity. For high-detail requirements, stereolithography (SLA) is used to produce the specimen in wax-like resin materials.

However, for reducing cost even further, standard fused deposition modelling (FDM) is being tested to produce specimens in simpler materials, such as e.g. PLA.

AM-assisted investment casting of complex heat sink geometries