World class X-ray equipment for academic and industrial applications

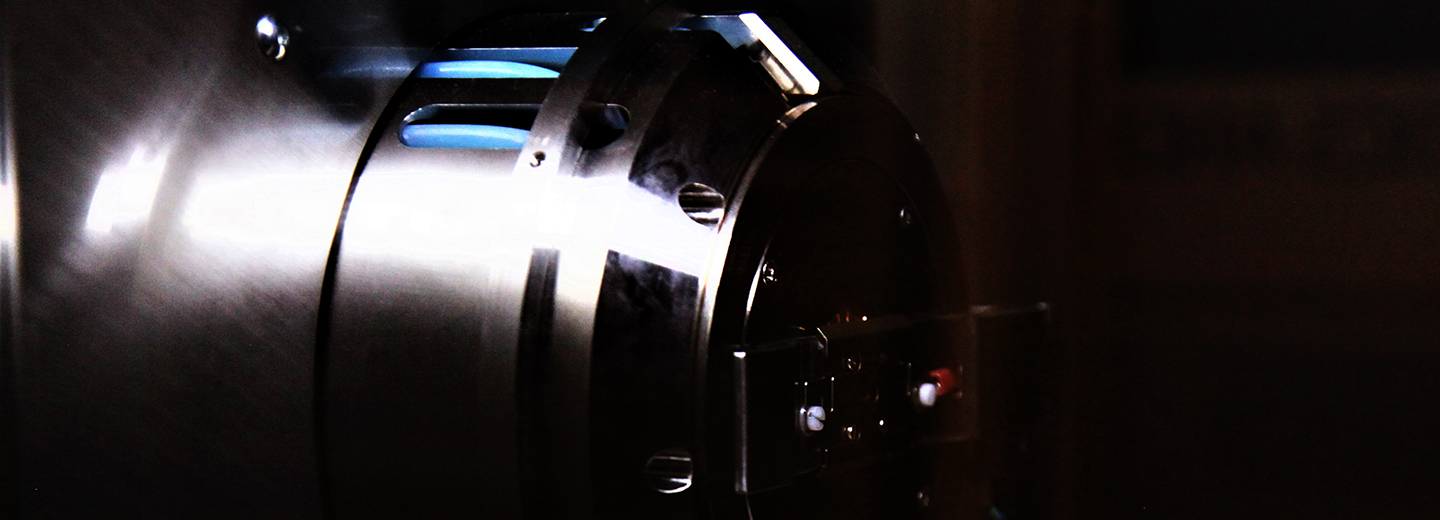

The Mads Clausen Institute has acquired a SKYSCAN 2214 which is one of the finest x-ray tomographs in the world. It has an incredibly large resolution and can be applied in a large range of industry applications.

- It is not one-of-a-kind, but it’s close to, says associate professor Serguei Chiriaev from the Mads Clausen Institute.

And he is right. Because there is not one but just two of the new model SKYSCAN 2214 machines from Bruker existing worldwide. It is thus the most outstanding equipment within tomography and x-ray analysis. One of the two machines is located at Alsion.

- It is exceptionally good at imaging incredibly fine materials. Its resolution is so high that we can focus on materials down on the scale of millionth of millimeters, nanometers.

Serguei Chiriaev is one of the specialists who are part of SDU Imaging. SDU Imaging is a cross-faculty initiative that aims at supporting and presenting the unique imaging activities and techniques that SDU provides. The initiative is there to promote the collaboration between university and industry. And MULTISCALE X-ray nanotomograph SKYSCAN 2214, as the full name of the new machine reads, has a long range of applications just for industry.

It is amazingly flexible and thus has rich possibilities for application. It can imagine all from biological material to electronic components and circuits.

Especially in connection to electronics the SKYSCAN 2214 has an advantage.

- You do not need to open up the component because you use x-rays. It’s just like you know it from the dentist or the hospital. This is why SKYSCAN 2214 is so highly useful in connection to, e.g., failure analysis of electronics, says Serguei Chiriaev.

Watch the video:

Try SDU’s unique equipment

With advanced imaging you can create two and three dimensional images down at micro and nanoscale which give you insights into materials’ specific characteristics, how they change over time, failure analysis and root causes for a given problem. SDU is using it for research, quality control and prototype development. And this is exactly what you can do, too.

Call SDU or send an e-mail and we’ll find out together. It is fairly simple and follows five simple steps:

- your specific problem will be discussed

- optimal techniques, measurements and investigations will be defined

- an agreement will be settled about the set-up of the joint project (research collaboration, student collaboration, external services or other)

- the investigation will be carried out at SDU

- you’ll receive the results and a report from an expert

If this got you interested, contact one of SDU’s business advisors, Frank Jürgensen or Frederik Gottlieb.