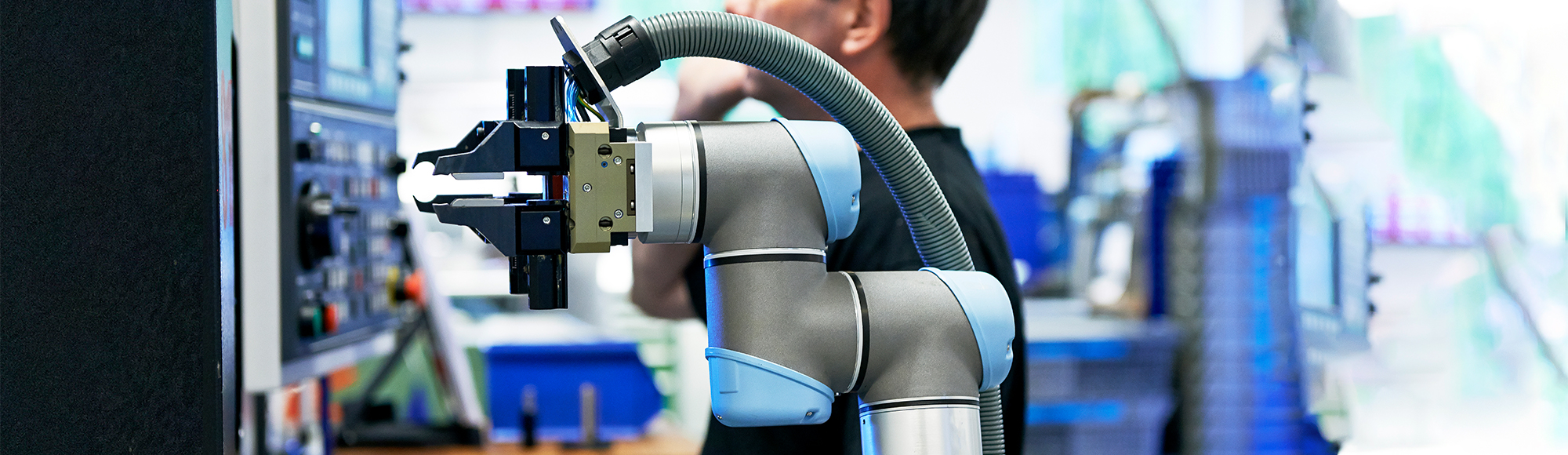

New technology to make robots attractive to smaller companies

Many companies avoid the use of robots, because they are simply too difficult to operate. A new research project aims to develop a robot technology tailor-made for small productions, which will be able to handle assembly processes and can easily be adjusted to new tasks.

Even though the fourth industrial revolution is roaring, many companies are hesitant to jump on the Industry 4.0 bandwagon and invest in a robot.

With consumer demand for specific products and customization, it is too costly for production companies to hire experts who can reprogram the robots to handle new products.

But now, researchers and companies have joined forces to develop a robotics solution tailor-made for small productions.

”A robot can easily move an object from one place to another. But it gets a lot more complicated when the robot has to put together two objects in an assembly process

- We are to develop a robot technology that can minimize the costs of automation of assembly processes at the company Terma.

Terma typically produces a small number of components at a high value. That makes flexible and easily reprogrammable robots essential, says associate professor Christoffer Sloth from SDU Robotics:

- A robot can easily move an object from one place to another. But it gets a lot more complicated when the robot has to put together two objects in an assembly process.

Small productions

Christoffer Sloth is the project manager of PIRAT, a project that is supported by $ 1.5 million from Innovation Fund Denmark.

In cooperation with the Odense-based robot giant Universal Robots, Terma and Technological Institute the project aims to create a whole new method for programming collaborative robots, which might turn out to be the new bestseller of Universal Robots.

According to the report Winning the Industry 4.0 Race from Innovation Fund Denmark, Danish companies risk collapsing from the strain of wage costs in the global competition, if they do not introduce automatic working procedures.

And it is not necessarily a lack of interest in the new technologies that is halting the progress. Many Danish companies have small productions, where the current robotic solutions are simply not profitable.

A robot with potential

Universal Robots, the biggest robot company in Denmark, also see the potential for a robot that is able to perfect assembly processes and at the same time easily reprogrammable.

- Assembly processes in general is one the big jobs in the industrial sector that is barely automated – especially in the typical Danish production that is characterized by small batches and frequent change, says Anders Billesø Beck, Innovation Manager at Universal Robots:

- Our collaborative robots are perfects for this, because they were initially developed with the Danish market in mind, and that market mostly consists of small and medium-sized companies who need flexible robotic solutions.

”It can be coded by an employee, who physically takes the arm and shows the desired action

A central part of the project is that non-experts must be able to program the robot, because small productions cannot afford a professional programmer to reprogram the robot.

- The goal is that everyone will be able to program our robot. It can be coded by an employee, who physically takes the arm and shows the desired action, which creates a pattern for the robot to save.

The action may need to be repeated a couple of times, before the robot understands the pattern completely.

No mistakes allowed

But simultaneously with not needing a computer, the robot is not allowed to make mistakes. The technology must result in at least 99 % correct assembly tasks.

- A part of the stability of the technology is in the force sensors that measure if the robot completes the assembly process.

-If the robot misses when trying to assemble two items, the sensors will notice and send information to the robot’s computer, so the robot is adjusted and hopefully doesn’t miss the next time, Christoffer Sloth explains.

Meet the researcher

Associate Professor Christoffer Sloth from SDU Robotics researches in the safety of collaborative robots that physically interact with humans. In addition, he utilizes his background within modeling and control to optimize robotic systems.

Facts

- Title of the project: Programming Ignition for Robotic Assembly Tasks, PIRAT

- Project partners: University of Southern Denmark, Universal Robots A/S, Terma, Technological Institute