Imaging technology

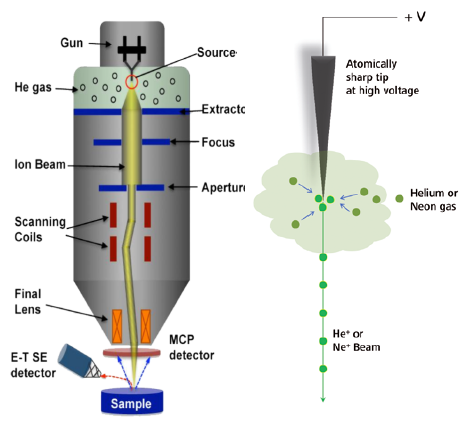

The heart of the ORION helium ion microscope is the gas-field-ion source (GFIS) that is an adaptation of the old concept of the gas field microscope.

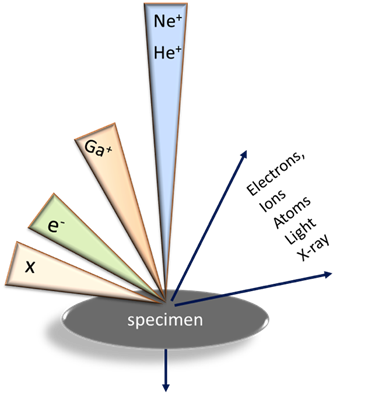

The beam generated by GIFS is conditioned and aligned by electrostatic lenses and scanned over the sample surface where it generates the imaging signals, such as of secondary electrons, back-scattered ions, and others. These signals are further collected by the corresponding detectors and processed by the image acquisition system.

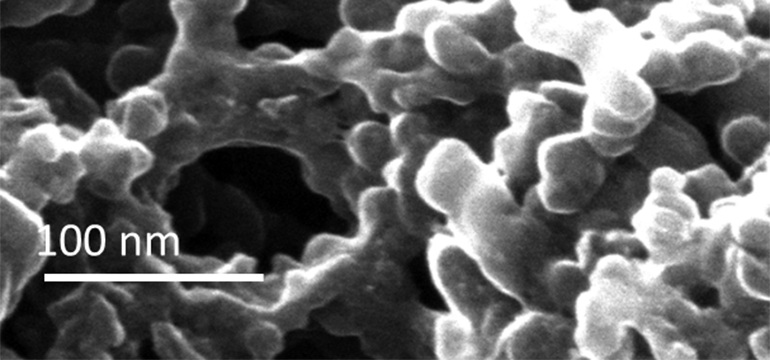

The superior spatial resolution (~0.3 nm) and other advantages of the ORION helium ion microscope originate from a number of factors specific to the ion beams, such as:

-

Extremely high brightness of the ion-source

-

Very small interaction volume and chromatic energy spread

-

Broglie wave-length and beam convergence are much smaller than in SEM.

Sample charging of electrically insulating samples in ORION can be efficiently compensated by the build-in electron flood gun because the sample charging in an ion microscope is positive and relatively small due to small probe currents. This significantly simplifies sample preparation procedures and improves resolution of the surface features.

Nanofabrication capabilities

Nanofabrication tools of ORION include:

- He and Ne beams generated by GFIS and used for fabrication of very fine structures by ion sputtering (ion milling)

- Gallium ion source for sputtering away relatively large volumes of matter

- Nano-patterning Visualization Engine (NPVE), which is a complex of soft- and hardware that provides nanopatterning and imaging of the nanopatterns in a single process.

Combining Ga and He ion beams in one instrument gives ORION unique tomography capabilities realized as a sequence of layer-stripping and imaging steps performed with Ga and He ion beams respectively.