Robots are Now Able to Imitate Human Work

Researchers at the Faculty of Engineering have now succeeded in creating a robot-system which can imitate human actions. Simultaneously, the robots are able to learn from their experiences. This might ensure that more manufacturing jobs remain in Denmark.

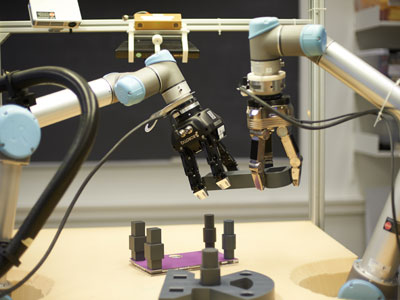

A man assembles four blocks. A robot-hand stands before him with its camera eyes fixed on the man’s work. When the man has finished assembling the blocks into the desired shape, the robot’s fingers begin to imitate the acts and assemble the four blocks in exactly the same manner.

- The robot observes the man’s movements with 3D-cameras. It inculcates the movement pattern and repeats it. The robots can successfully handle 4-5 different objects, and we are able to introduce new objects, says Professor Norbert Krüger from the Maersk Mc-Kinney Moller Institute.

Practice makes the robots work faster

The researchers have had great success with getting the robots to perform a specific task by demonstrating how to do it. This allows the researchers to programme the robot by simple demonstration. In addition, researchers from the Faculty of Engineering have taught the robots to learn from their experiences.

- We noticed that the robots assembled the blocks quicker every time they tried to assemble an object. The first time the robot had to assemble the blocks it took 40 seconds. The second time it only took 20 seconds. This means that the robot is able to learn from its experiences, says Norbert Krüger.

The project is a part of the three-year-old European research project called IntellAct. The aim of the project is to get robots to understand human actions in a production context and independently perform these. The researchers’ results can revolutionise the manufacturing jobs.

- By combining research results from partners of the project, we are able to build a system in which the robot, for example, is able to find a nut and screw it onto a bolt. Assembling an object and placing it in a hole is a universal action that happens frequently in the production, says Thiusius Rajeeth Savarimuthu from the Maersk Mc-Kinney Moller Institute, and the next stop is now to test the technology in the industry.

- It will mean a great deal to companies if they can programme the robots by simple demonstration instead of having an expensive robot-engineer come out and programme the robot each time it is to perform a new task, says Norbert Krüger.

No need to relocate jobs

Today, robots are too expensive for small- and medium-sized companies. Therefore, a lot of manufacturing companies relocate their packing and assembling tasks to, for example, China where wages are much lower. But with flexible robots there will no longer be any financial gain in transferring workplaces to low-wage countries.

- It is important for the whole of society that we can keep our industrial enterprises. Previously, the politicians did not think we could survive on knowledge-intensive jobs when the development departments stayed home. However, it has proven to be a hassle for a majority of the companies to have their production- and development departments separated, so the development departments often follow the production departments abroad. Therefore, we need to work to preserve manufacturing jobs in Denmark, says Norbert Krüger.

Contact

Professor Norbert Krüger from the Maersk Mc-Kinney Moller Institute: 2778 7483, Norbert@mmmi.sdu.dk

Assistant Professor Thiusius Rajeeth Savarimuthu from the Maersk Mc-Kinney Moller Institute: 2440 9545, trs@mmmi.sdu.dk